Ensure Regulatory Compliance and Workforce Health

by Spencer Eppler, CSP, CEAS, Executive Vice President, WorkSTEPS

Does your operation include the processing of materials containing silica?

If so, it’s a top priority to protect your people from harmful exposure to silica dust as part of your environment, health, and safety (EHS) program.

In Part One of this series, we will consider a recent example of one employer who disregarded this responsibility, with grave ramifications. Also, we will outline the hazards of silica dust and look at current requirements of the Occupational Safety and Health Administration (OSHA) and Mine Safety and Health Administration (MSHA).

See Part Two for a discussion on how and why to proactively ensure workforce safety during silica exposure – including the vital use of appropriate controls.

Employer Cited for Violations

The August 2024 Department of Labor headline read, “Chicago countertop maker faces dozens of violations, $1M in penalties for not protecting workers, including 2 with incurable lung disease, from silica dust.”A 31-year-old employee of Florenza Marble & Granite needed a double lung transplant after crystalline silica exposure, and his 59-year-old father and coworker also awaited a lung transplant. Both had limited English proficiency and had received no information or training from the employer about silica exposure.

Inspectors found employees working in a haze of silica dust (nearly 6x permissible levels) and misusing respirators, with few controls to manage exposure as employees cut engineered and natural stone countertops. The owner had not developed a safety program, even though two workers’ compensation insurance carriers had refused to insure the company for not providing air sampling or proof that it protected its workers.

Willful OSHA violations included:

- Failing to establish a baseline of employees’ medical health

- Not performing medical surveillance to monitor exposure

- Lacking controls to reduce silica dust to safe levels

- Exposing workers to unsafe levels of silica dust

- Failing to have a respiratory protection program in place

Clearly, you don’t want this to happen at your facility. Ensure you understand the risks and comply with safety regulations to protect your valuable workforce.

Silica Exposure

Crystalline silica is a mineral found in construction materials such as sand, stone, concrete, brick, mortar, glass, and pottery. Even technological equipment such as computers and phones contain crystalline silica. Without silica, our houses, roads, and transportation systems couldn’t exist – nor would our internet infrastructure, renewable energy programs, and telecommunications systems.

The silica contained in these finished products is not known to be harmful. However, when workers cut, grind, drill, or crush these materials, tiny dust particles can be produced and inhaled, traveling deep into their lungs. This crystalline silica dust exposure can occur during standard job functions, including:

- Using masonry saws, grinders, drills, jackhammers, and handheld powered chipping tools

- Operating vehicle-mounted drilling rigs

- Milling or operating crushing machines

- Using heavy equipment for demolition or other tasks

- Conducting abrasive blasting and tunneling operations

Silica-Related Diseases

Per OSHA, around 2.3 million American workers are exposed to crystalline silica dust. When inhaled, this dust is toxic and can lead to severe health issues and illnesses, including:

- Silicosis – an incurable lung disease

- Chronic silicosis – occurring over 10-30 years of exposure

- Accelerated silicosis – developing within five years of high exposure

- Acute silicosis – occurring within weeks of high-level exposure

- Bronchitis – with airway inflammation

- COPD – chronic obstructive pulmonary disease

- Autoimmune diseases – including lupus and rheumatoid arthritis

- Increased risk of kidney disease and lung cancer

Regulations around Silica

Both OSHA and MSHA have published regulations to protect workers exposed to silica dust. Following is a summary.

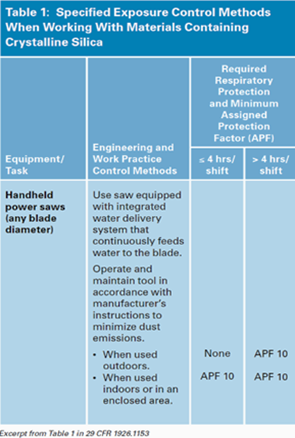

OSHA: The 2016 OSHA construction standard 29 CFR 1926.1153 requires employers to limit worker exposure to respirable crystalline silica and take steps to protect them. Employers can use a control method per Table 1 or independently decide which controls best meet the permissible exposure limit (PEL):

- Determine the amount of silica exposure if at or above the action level of 25 μg/m3, averaged over an eight-hour day

- Protect workers from exposures above the PEL of 50 μg/m3 (micrograms of silica per cubic meter of air), averaged over an eight-hour day

- Use dust controls and safer work methods to protect workers above the PEL

- Provide respirators when dust controls and safer work methods cannot limit exposures to the PEL

The OSHA general industry and maritime standard for respirable crystalline silica is 29 CFR 1910.1053. It requires employers to:

- Determine the amount of silica exposure if at/above the action level of 25 μg/m3, averaged over an eight-hour day

- Protect workers from respirable crystalline silica exposures above the PEL of 50 μg/m3, averaged over an eight-hour day

- Limit access to areas where workers could be exposed above the PEL

- Use dust controls and safer work methods to protect workers from silica exposures above the PEL

- Provide respirators when dust controls and safer work methods cannot limit exposures to the PEL

In addition, for all types of employers where workers are exposed to crystalline silica, OSHA requires companies to:

- Establish and implement a written exposure control plan

- Restrict housekeeping practices that expose workers to silica

- Offer medical exams (chest X-rays, lung function tests) initially, and every three years

- Train workers on risks, tasks that can expose them, and ways to limit exposure

- Keep records of workers’ silica exposure and medical exams

MSHA: In April 2024, MSHA published its final rule, “Reducing Miners’ Exposure to Respirable Crystalline Silica.” The regulation’s effective date was June 17, 2024, with MSHA 30 CFR Part 60 updated July 2024. This ruling benefits about 250,000 U.S. miners after a rise in silica-induced conditions. Coal mine operators were required to comply within 12 months of the June publication date, and metal and nonmetal (MNM) mine operators were given 24 months to comply.

The MSHA ruling:

- Lowers the PEL for respirable crystalline silica to 50 µg/m3 for a full shift, calculated as an eight-hour time-weighted average (TWA)

- Establishes an action level at 25 µg/m3 for a full shift or eight-hour TWA

- Includes uniform requirements for controlling and monitoring exposure at coal and MNM mines

- Includes medical surveillance requirements for MNM mines, modeled on existing surveillance requirements

- Updates respiratory protection requirements by incorporating voluntary American Society of Testing and Materials (ASTM) standard ASTM F3387-19 Standard Practice for Respiratory Protection

Keeping up with these regulatory laws and changes is an understandable burden for companies – large and small. It’s challenging for safety professionals to allocate the time needed to manage the process; many companies simply don’t have the resources. Remember that workforce training and education is part of this ongoing responsibility – for new and current employees – and may require information in several languages.

Across industries, we are seeing a trend toward companies seeking third-party partners to help. For example, WorkSTEPS has experts such as industrial hygienists who go onsite to help understand and evaluate workforce risk, implement mitigation plans, and then monitor workers – keeping employees safe and employers compliant.

Continue to Part Two of this series on protecting your workforce from silica dust.

Click here to learn more about WorkSTEPS.

Spencer Eppler is the Executive Vice President of Occupational Medicine and Safety at WorkSTEPS. He is a Certified Safety Professional (CSP), Certified Ergonomic Assessment Specialist (CEAS), industrial hygiene technician, and a former National Registry Paramedic. Spencer is a member of the American Society of Safety Professionals and has more than 23 years of experience in safety and health.

He holds a bachelor’s degree in occupational safety and health, with a concentration in fire science.